Moldova Steel Works is a modern competitive steel producer

MSW is one of three steel plants built in the USSR in the mid 1980’s. Construction of the plant started in August, 1981 and the first steel cast was produced in October, 1984.

The plant has two main shops: the EAF shop and the Rolling Mill.

According to the initial design the plant had two EAFs (100 I6) and two CCMs with a total annual capacity of 700,000 t of steel. The total output in the first year of operation was as low as 206,000 t of steel billets because both the EAFs and the CCMs had design imperfections which made the efficient operation of these units impossible.

In 1985, Moldova Steel Works commenced a multistage project to upgrade and modernize main production units in the EAF shop. The project involved foreign contractors and suppliers of steel making equipment.

As a result, the plant shifted its total production to only one line (Line No.2: EAF + Ladle Furnace + Continuous Caster) in 1998. Line No. 1 was dismantled.

In 1997-2003, modernization projects were carried out by own forces. In September, 1999, the total capacities of the EAF (120 t) and the Continuous Caster reached 1,000,000 t of crude steel.

JSC Moldova Steel Works in numbers

Electric Arc Furnace (120 t):

120 t

Average tap weight

140 t

Maximum capacity (liquid steel)

95 MVA

Nominal power of the EAF transformer

≤ 7 m ³/t

Natural gas consumption

600 mm

Electrode diameter

≤ 40 m³/t

Oxygen consumption

EAF performance figures

31 casts

Daily number of casts

3,805.4 t

Daily output

47.0 minutes

Average tap-to-tap time

39.4 minutes

Power On time

362 kWh/t

Power consumption

The ever reached maximum monthly output was 92,090 t in May, 2004.

The secondary metallurgy is carried out in a Ladle Furnace and a VD/VOD vacuum degasser.

Ladle Furnace

25 MVA

Nominal power of the LF transformer

400 mm

Electrode diameter

≤ 4,5° C

Steel heating rate

≥ 40 minutes

Treatment time

0.3 m³/t

Argon consumption

The Ladle Furnace is equipped with a storage/weighing/feeding system for ferroalloys, wire feeding machines, and a feeding system to purge powder lime/coke breeze into steel.

A characteristic feature of the VD/VOD chamber-type steel degasser

≤ 110 t

Cast weight

≤ 12 minutes

High vacuum buildup time (≤ 5 mbar)

≥ 30 minutes

Treatment time

≤ 40 ppm

Total oxygen in steel after vacuum treatment

≤ 1,5 ppm

Total hydrogen in steel after vacuum treatment

≤ 60 ppm

Total nitrogen in steel after vacuum treatment

The VD/VOD degasser was installed in 2002. It uses dry mechanical pumps to ensure efficient degassing of high-quality steels at low production costs.

Technical characteristics of the Continuous Casting Machine

125 х 125 mm ± 3 mm

Billet cross-section

8000 - 12000 mm ± 100 mm

Billet length

Up to 46 casts

Casting sequence

Ladle-Tundish and Tundish-Mould sections

Stream shrouding

in moulds (M-EMS)

Electro-magnetic stirring system (EMS)

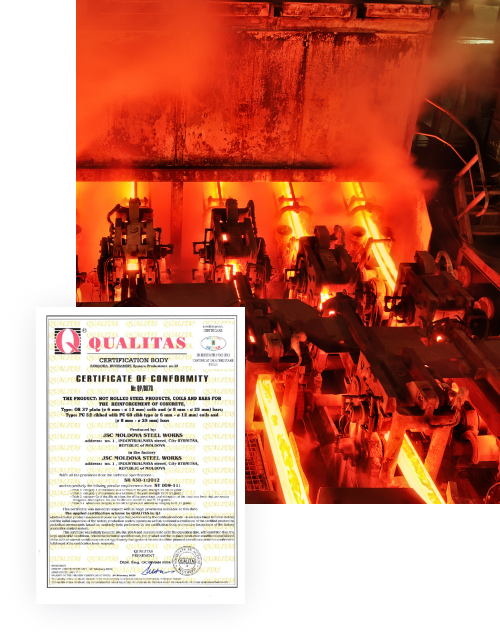

Rolling Mill

Rolling Mill

The continuous light-section rolling mill (320/150) was designed by Ukrghipromez, Ukraine. The set of main rolling equipment was manufactured and installed by SKET (Magdeburg, Eastern Germany).

The designed capacity was 500,000 t of rolled products per year and the rolling mill reached it in 1988. In 1990, the output was 540,000 t of rolled products.

The rolling mill was designed as a 320/150 combined one line rolling mill. Billets were rolled either in the bar line or in the wire rod line. In 1997, the rolling mill was redesigned and transformed into a two line rolling mill with a capability to roll bars and wire rod in two lines simultaneously.

In October, 1999, the controlled cooling line (STELMOR line) was extended up to 147 m (the covered section was 120 m long). The aim of this modernization project was to improve microstructure of wire rod and to start production of new kinds of rolled products such as deep drawing wire rod, low alloyed wire rod of welding quality, wire rod for springs and high strength ropes. The upgraded line provides flexible cooling conditions to produce high-quality steel wire rod in strict compliance with national and international standards at low production costs.

A new 110 m/sec wire block was commissioned in 2001. The annual output of rolled products reached 900,000 t.

The ever reached maximum monthly output of rolled products was 81,080 t in October, 2005.

Rolling Mill

The continuous light-section rolling mill (320/150) was designed by Ukrghipromez, Ukraine. The set of main rolling equipment was manufactured and installed by SKET (Magdeburg, Eastern Germany). The designed capacity was 500,000 t of rolled products per year and the rolling mill reached it in 1988. In 1990, the output was 540,000 t of rolled products. The rolling mill was designed as a 320/150 combined one line rolling mill. Billets were rolled either in the bar line or in the wire rod line. In 1997, the rolling mill was redesigned and transformed into a two line rolling mill with a capability to roll bars and wire rod in two lines simultaneously.

In October, 1999, the controlled cooling line (STELMOR line) was extended up to 147 m (the covered section was 120 m long). The aim of this modernization project was to improve microstructure of wire rod and to start production of new kinds of rolled products such as deep drawing wire rod, low alloyed wire rod of welding quality, wire rod for springs and high strength ropes. The upgraded line provides flexible cooling conditions to produce high-quality steel wire rod in strict compliance with national and international standards at low production costs.

A new 110 m/sec wire block was commissioned in 2001. The annual output of rolled products reached 900,000 t.

The ever reached maximum monthly output of rolled products was 81,080 t in October, 2005.

Sizes from 6 to 40 mm

«Deformed and plain reinforcing steel in bars and coils»

Wire rod

Diameters from 5.5 to 14 mm

Angle bars

Wing width: 25-50 mm, wing thickness: 3-5 mm

Channel

№ 5

In 1990, Moldova Steel Works adopted a short-term and long-term technical development policy to adjust to the fast paced environment in the international markets. Priority was given to production of new higher added value steel products from high steel grades.The company enjoyed improvement and dynamic development in every field of its activity, thus strengthening its competitive position in the steel market.

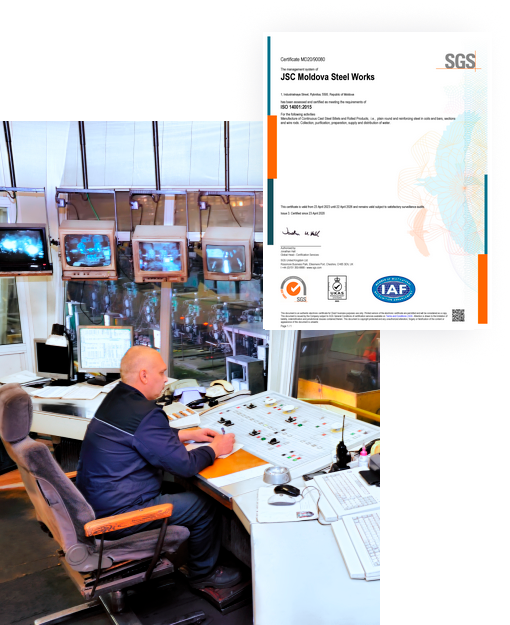

One of major steps was implementation of the Quality Management System and its certification for compliance with ISO 9002:94. A thorough review was carried out to study the experience of the German leading steel producers in the area of QMS implementation, as well as the requirements of TUF Certification Body, Brandenburg, Germany.

At the same time,based on a two-year training contract MSW had its key technical staff trained at HSW (Germany). The scope of training covered advanced production methods of the EAF steel melting, LF treatment and CCM casting.

In March 1995, MSW received its first Certificate of Approval (Certificate No. 936251to BS EN ISO 9002:94) from LRQA (UK) for its Quality Management System covering the manufacture of steel continuous casting billets and rolled products, including plain round bars and reinforcing deformed bars in coils and in cut lengths, sections and wire rod. Later, the MSW's Quality Management System was recertified by LRQA to BS EN ISO 9001:2000 and then to BS EN ISO 9001:2008.

Furthermore, within the scope of certification of reinforcing bars with UK CARES against the requirements of BS4449 according to the CARES Certification Scheme for Steel for the reinforcement of concrete, MSW received CARES Certificate of Approval No.1075 confirming the compliance of the Quality Management System with the requirements of BS EN ISO 9001:2008, and then, in 2018, with BS EN ISO 9001:2015.

In 2018, MSW received the SGS Certificate of Approval confirming the compliance of the Quality Management System with the requirements of ISO 9001:2015. In 2020, when MSW implemented the Integrated Management System (ISO 9001:2015 and ISO 14001:2015), SGS (Switzerland) granted its Certificate of Approvalconfirming the compliance of theMSW’s IMSwith the requirements of ISO 14001:2015.